The post goes on to explain the worries that led on the PUPSIT need: “Concerns have already been elevated that a sterilizing filter could develop particular flaws that might enable microbiological contamination to move during filtration. The important thing is always that flaws may very well be blocked or clogged by fluid contaminants or parts in the course of the filtration course of action and keep on being undiscovered all through submit-use integrity take a look at. This phenomenon is sometimes called ‘filter flaw masking’” (one).

If these products and solutions are usually not processed aseptically, it could persuade contamination. Unfortunately, due to the fact they are right injected into sensitive membranes, contaminated solutions can severely impact the tip consumer.

Liquid bottle filling machines provide important Value discounts and contribute to squander reduction, generating them an invaluable asset in marketing sustainable practices throughout the pharmaceutical market.

Exposure of settle plates (petri dishes of nutrient agar) at crucial positions in just the overall space where the equipment is sited.

Why is lyophilization made use of when generating parenteral medicines? As the amount of sophisticated drug products which pose stability challenges turn into more popular and also a liquid dosage sort is impossible, drug builders convert to sterile lyophilization.

This agility in catering into a broad selection here of solutions not only improves marketplace responsiveness but will also fosters client satisfaction, that's important for developing brand name loyalty and retaining a aggressive edge.

Just one click on the contact monitor is sufficient to start out the sealing process. Just Stick to the Guidelines displayed.

Several of different shut methods that will probably be included into these manufacturing layouts include shut bioreactors, media and reagent supply units, sampling and monitoring systems, harvest and purification units, waste administration programs, and integrated control and automation programs.

Multi Channel Customized methods for virtually any check here quantity of channels around (24). Presented in possibly Rotary or Linear dispense techniques. Unbiased dispensing parameters can be custom-made as necessary with uncomplicated programming.

Likewise, robotic operations have also grow to be very important for automatic aseptic processing as they permit for the clever management of data even though giving comprehensive information of all operations. These robotic systems are equipped with different sensors which can straight away detect any drift developments and/or manufacturing nonconformities.

Applicable only to applicants implementing into a position in any location with pay back disclosure requirements underneath state or regional regulation:

Solution filter shall be wetted with product or service Remedy, its integrity is analyzed, and activity is recorded in BMR.

Similar SOP need to be revised to include the usage of a checklist to guarantee the absence of any empty glass bottles within bottle washing equipment throughout breaks and at the end of change. The checklist need to be counter-signed by device supervisor.

Our experienced staff can create and regulate your pilot creation to ensure all the things goes smoothly.

Taran Noah Smith Then & Now!

Taran Noah Smith Then & Now! Rachael Leigh Cook Then & Now!

Rachael Leigh Cook Then & Now! Justine Bateman Then & Now!

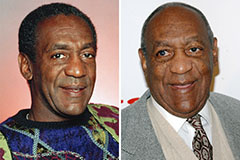

Justine Bateman Then & Now! Bill Cosby Then & Now!

Bill Cosby Then & Now! Katey Sagal Then & Now!

Katey Sagal Then & Now!